Our products are in demand worldwide, and across all industry sectors.

Wherever we supply, the story is the same: our sealing technology delivers increased reliability, demonstrated by increased mean time between failures.

Today we are working with an impressive portfolio of customers, in an equally impressive range of industries.

Solutions

In the development of our mechanical seals, we use state-of-the-art simulation and CAX programs. This ensures the perfect function in the early development phase.

Among other things, we use self-developed simulation programs, finite element analysis (FEA) and computational fluid dynamics (CFD). Together with our extensive product validation and test program, our leading sealing technology is developed. All this to ensure that our customers' systems have a longer service life and fewer failures.

Improve reliability without modifying your existing equipment

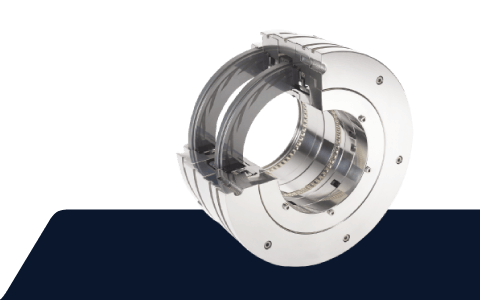

AESSEAL - Torishima has made an enormous investment in modular design which includes custom-engineered specials. For you the customer this means a value-for-money solution and the best on-time delivery performance in the industry. AESSEAL - Torishima uses 9-axis machine tools, each of which has over 300 tool positions, so we can supply your engineered special on demand.

Investment

Over 7% of annual sales revenue has been reinvested in R&D over several decades. This has almost certainly led to the most advanced range of sealing technology available globally.

The Complex made Simple

Custom-engineered sealing solutions are often required for difficult applications including mechanical seal support systems which improve the environment the seal operates in for safe and reliable sealing.

Testing to API 682

Our entire CAPI™ seal range meets the test requirements of API 682.

Application Engineering

AESSEAL® has invested millions of dollars in Product Life-cycle Management (PLM) infrastructure. The major customer benefit is extended seal life from quality custom engineered seals.

Design to Manufacture

All products are developed in 3D CAD which is fully integrated with CAM. CAM controls and drives all machine tools centrally. Integration with PLM ensures control of changes so we can deliver products quickly, affordably and repeatably.

Test Capability — gas and conventional wet seals

- Speeds to 45000 rpm

- Pressures to 5000 psig (350 barg)

- Temperatures to 280ºC (536ºF)

Awards, Memberships & Associations

Have you ever been so impressed with your supplier’s quality and service that you gave them an award?

Out of all our awards, the customer service ones mean the most. This is because we believe in putting the customer at the heart of our business.

Our philosophy is simple: we’ll do whatever it takes to deliver, wherever and whenever it’s needed. Our aim is to consistently exceed expectation and meet even the most complex briefs and challenging lead times.