Explore Our Case Studies

Discover how AES Engineering Group is making a difference for companies worldwide, saving customers money, reducing downtime, and enhancing health, safety, and environmental impact.

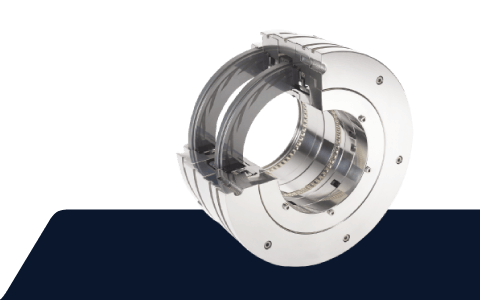

LabTecta puts a stop to eight-year oil leaks

Chemical plant saved over €500,000 in the first year

Chemical Producer Saves Over £1.7 Million in Plant Downtime

Counterproductive flush water in an evaporator pump leads to big savings

During an energy audit at a Canadian pulp and paper plant, AESSEAL identified 15 packed evaporator area pumps that needed upgrading to mechanical seals.

Fantastic seal life for notoriously difficult application

A pulp & paper company in the Canada were dissatisfied with the reliability of the mechanical seal used in its Chlorine Dioxide generator pump.

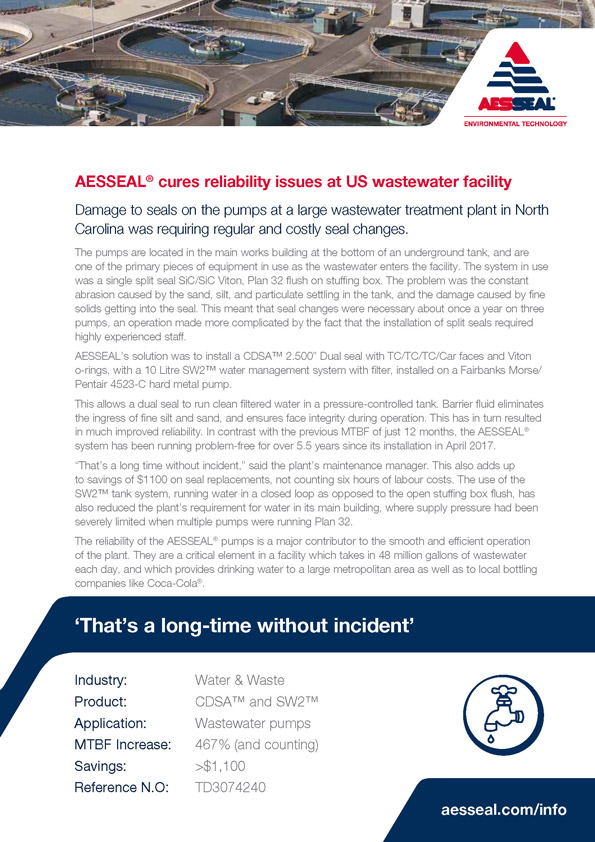

AESSEAL cures reliability issues at US wastewater facility

Damage to seals on the pumps at a large wastewater treatment plant in North Carolina was requiring regular and costly seal changes.

Reliability upgrade improves Mean Time Between Failure by 5 times

Major chemical company SASOL were experiencing premature seal failure on one of its process pumps.

Reliability upgrade saves over ZAR200,000 in just 10 months of operation

A copper, zinc and lead mine in South Africa was experiencing reliability issues with three of their mine de-watering pumps.

Mining company saves $8 million AUD with AESSEAL system

The aggressive nature of the coal mine water slurry was not only damaging the seals, but was also causing bearing failure and large amounts of downtime.

LabTecta reduces quality issues and improves reliability

A paper manufacturer in the USA was experiencing oil leakage from the journals in the dryer section of its paper machine.

LabTecta seals solve leakage problems

A paper mill in the Northwest United States was experiencing persistent problems due to lubricant contamination in its refiners.

Huge cost savings for US company with Magtecta unit

A US paper manufacturer has reported savings of more than $27,000 over just three years following the installation of an AESSEAL MagTecta™ unit.

LabTecta upgrade increases MTBF rate by over 2000%

A food and beverage manufacturer in Ireland was seeing failure rates as often as 2 months on their Auger screw transfer pump.

Process manufacturer sees a 540% increase in MTBF rates

A leading paint manufacturer was experiencing unacceptable reliability levels on a badly aligned bottom entry paint mixer.

Cartridge seal simplifies maintenance and improves reliability

Pump repair specialist, Production Pump in the USA were looking to improve the reliability of a pump for one of its customers in the Oil and Gas Industry.

Full steam ahead for refinery after change to STS seals

An oil and gas refinery in northern England was experiencing poor reliability of its steam turbine resulting from the failure of its existing seal system.

Improved Safety and Reliability

A major manufacturer in the UK was having reliability issues with the seal on a critical Labour chemical pump used to pump caustic solution.

AESSEAL helps UK firm to multi-million pound savings

A leading UK company is set to save more than £5 million over five years following the installation of AESSEAL LabTecta OP bearing protectors.

Significant savings with new AESSEAL system

A corn milling company in the Midwest of the United States is in line to save hundreds of thousands of dollars